Electrostatic Discharge (ESD) poses a significant threat to sensitive electronic components and devices at every stage of the supply chain. From manufacturing to distribution, implementing proper ESD packaging solutions is essential to mitigate risks and maintain product integrity. In this guide, we will explore practical tips for selecting and utilizing ESD packaging effectively.

Understanding ESD Hazards in Shipping.

During the shipping process, electronic products are vulnerable to various ESD threats identified by the ESD Association (ESDA), including:

1.Triboelectric Charge Generation: Occurs when non-charged materials rub against electrically charged items.

2.Direct Discharge: Direct transfer of static charge between objects.

3.Electrostatic Fields: Presence of static electric fields that can induce charges in nearby objects.

To safeguard products against these hazards, specialized ESD packaging is indispensable.

The Role of ESD Packaging.

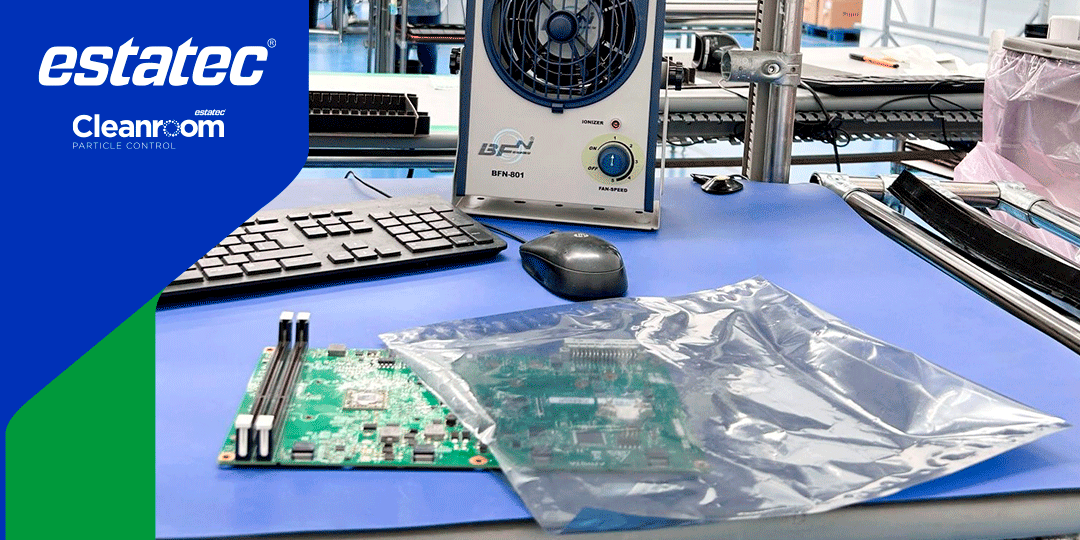

ESD packaging serves a dual purpose: shielding products from internal and external electrostatic charges and providing physical protection against damage. Common ESD packaging options include shielding bags, corrugated boxes, and semi-rigid plastic packages, catering to products of all sizes.

The Science Behind ESD Packaging.

ESD packaging materials exhibit high surface resistivity, typically rated at no more than 1.0 x 10^3 ohm-cm. These materials prevent the buildup of static charges within the package and facilitate the dissipation of external charges. Guidelines outlined in IEC 61340 define three levels of ESD packaging:

1.Intimate Packaging: Direct contact with the product.

2.Proximity Packaging: Encloses the product without direct contact.

3.Secondary Packaging: Provides physical protection only.

The choice of ESD packaging depends on the electrostatic sensitivity of the products and specific manufacturing requirements.

By understanding ESD risks and employing appropriate packaging solutions, manufacturers can uphold product quality and customer satisfaction, ensuring smooth operations from production to delivery.